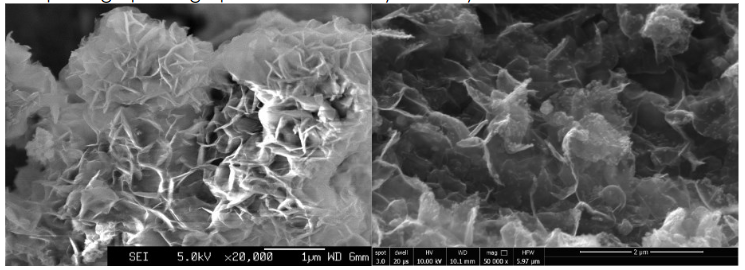

Graphene is very exciting and one of the best materials in the last decade. The interest in producing non-expensive and high-quality graphene is of great interest to many Departments of materials and researchers worldwide. The main goal of this research considers the design, development, and optimisation of new technology for producing graphene by electrolysis in molten salts using constant cell voltage, reversing cell voltage, and constant overpotential and reversing overpotential methods. Compared to other processes, the electrolysis process is simple, ecological, and economical. Furthermore, it offers possibilities to control various parameters: type of electrolyte, applied voltage, current density, temperature and type of graphite used as a row material for synthesis of graphene. The underlying relationship between the parameters and the quality of the graphene is obtained through an explainable tree-based Machine Learning (ML) model. We trained the model by using the production process parameters as input attributes and the quality of the produced graphene as a target variable. Domain experts provide labels regarding the quality of each experimental instance in our data set. We propose using the extracted rules from the model to serve as a blueprint for optimal graphene production by electrolysis in molten salts. Choosing the correct values for the process parameters results in high-yield graphene production, up to ten times cheaper than the one produced with other existing technologies.

Download “Article” Towards_Optimal_Production_Graphene.pdf – Downloaded 157 times – 714 KB

Download a copy of the manuscript